Manufacturing Technology | Are You Ignoring The Safety of This Team Member? |

Imagine the uproar and ensuing repercussions if, upon inspection, you found people on the factory floor working without using proper safety equipment. It would only be a matter of time before someone got fired, hurt, or worse. Left uncorrected, there are bound to be work stoppages and lose of production, all because someone tried to take safety shortcuts.

Imagine the uproar and ensuing repercussions if, upon inspection, you found people on the factory floor working without using proper safety equipment. It would only be a matter of time before someone got fired, hurt, or worse. Left uncorrected, there are bound to be work stoppages and lose of production, all because someone tried to take safety shortcuts.

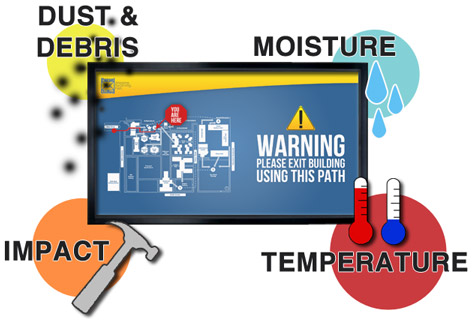

Most likely, there is a valued member of the production team that is already being victimized by a lack of safety protection: Manufacturing Metric Displays or other Digital Signage used on the production line or factory floor. Much time is spent in determining what production metrics and corporate communications messages will be most useful to display on these screens. (To learn about the benefits of Manufacturing Metric Displays, check out this article on manufacturing technology.) However, it is just as imperative to consider how to keep this manufacturing technology protected so these messages can continue to be displayed without lost time due to accidents or preventable malfunction. There are environmental conditions that exist in today’s factories that can raise concern. Let’s examine the top four:

Is Your Manufacturing Technology Protected?These potential risks to the health and well-being of data displays, and as importantly to factory floor communications, warrant an appropriate response. There are a few options out on the market. Some TVs are manufactured in such a way to be self-sealed and weather tight. These units have built in heating and cooling units as well, enabling operation despite fluctuations in outside temperatures. One thought to keep in mind: All weather screens are more costly than standard LCD’s. Since LCD screens have a usable lifespan of five years, an entirely new unit would need to be purchased and replaced when it ceases to function.Have you ever considered putting a hard hat on your screens? That is the kind of protection your displays get when they are mounted in a LCD enclosure. As a piece of manufacturing technology designed to be installed in factories, enclosures accommodate displays ranging in size from 32" to 82". Thus, your metric display stays in an environmentally sealed enclosure, protected in high traffic areas where accidents and various atmospheric conditions can create problems. Most enclosures include anti-reflective and shatter resistant glass, integrated thermal management and tamper resistant locking mechanisms. The display enclosures can be mounted on a wall, ceiling or post. Also, when the standard LCD screen reaches end of life, simply put the replacement display back into the enclosure. With using an all-weather display or an enclosure, the question arises about what to do to protect the brain center of your metric displays: the digital signage player. Many signage players are PC –based, which have all the moving parts and operational temperature limitations inherent to PC’s. This presents a special challenge for installing and operating these systems in the varying conditions found in factories. To account for this, the Noventri Eco-Series SF-200 Digital Signage player is manufacturing technology specifically assembled to be environmentally agnostic. By virtue of its solid state design, there are no moving parts to fail, and the SF-200 has been put through severe temperature testing to ensure it can withstand heat and cold. Also, with its diminutive size, it can be mounted to the back of an LCD screen for ease of installation, making it an ideal choice for manufacturing facilities. As an important part of production management and helping ensure smooth operations within the factory, manufacturing technology needs to be safely protected from the harsh elements to which it is exposed. Through the use of LCD enclosures and a solid state player such as the SF-200, your metric displays will function efficiently for years to come. For more information or to request a free demo click the button below. |

|

|

|

|

|

|