Safety Metrics | 4 Steps That Make a Difference |

For safety metrics to have real value to manufacturers they must be used as a basis for change and those changes need to be communicated clearly to the workforce. Why?

For safety metrics to have real value to manufacturers they must be used as a basis for change and those changes need to be communicated clearly to the workforce. Why?

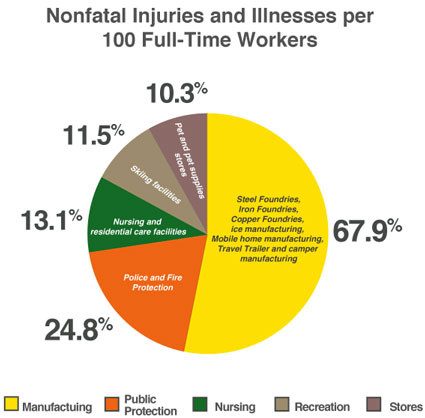

As manufacturers continue to look for methods to increase production yield, risk management also becomes a critical success factor. Work hours lost due to injury means less production. And manufacturing can be hazardous business. A study published on ManufacturingWeekly.com1 based on the The Bureau of Labor Statistics2 findings highlight this fact. Safety really comes down to each and every member of the organization being safety conscious and well informed about proper procedures. The big challenge is often communicating accident prevention methods and reminders throughout the various departments and sectors of the workforce, from management to engineers to technicians to line workers. What can be done to spread the word about safety initiatives and sharing safety metrics so they impact your factory? Consider these four areas:

Recommended Delivery of Safety MetricsWith digital safety scorecards, you gain the ease at which the latest safety information can be posted. No need to perform a “great paper chase” through the facility to replace and update static signs or whiteboards. This can now be done by pulling the data automatically utilizing ODBC connections. With years of experience specializing in automated communications, Noventri knows the powerful impact MMD’s and safety digital scorecards can have in helping organizations reach their production goals in an efficient and safe manner. To learn of more ways these can be utilized in your facility, check out our Manufacturing Metric Displays or browse our library of Manufacturing Articles.1 ManufacturingWeekly.com, http://www.manufacturingweekly.com/where-were-the-most-workplace-injuries-in-the-manufacturing-industry/ 2 The Bureau of Labor Statistics, http://www.bls.gov/news.release/archives/osh_10252012.pdf For more information or to request a free demo click the button below. |

|

|

|

|

|

|