Manufacturing Metrics | Simple Solutions to a Complex Problem |

Are you harnessing the true power of all the manufacturing metrics gathered in your facilities? How can you make that data actually work for you? It is a complex problem. The answer is simple, automation.

Are you harnessing the true power of all the manufacturing metrics gathered in your facilities? How can you make that data actually work for you? It is a complex problem. The answer is simple, automation.

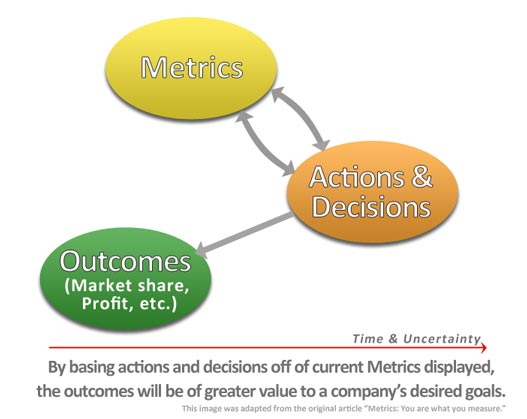

When the term “manufacturing automation” is used, it generally refers to systems automation. Wikipedia1 defines the term as the following: “Automation or automatic control, is the use of various control systems for operating equipment such as machinery, processes in factories, boilers and heat treating ovens, switching in telephone networks, steering and stabilization of ships, aircraft and other applications with minimal or reduced human intervention. Some processes have been completely automated.” The article goes on to say that the ‘biggest benefit of automation is that it saves labor, however, it is also used to save energy and materials and to improve quality, accuracy and precision.’ With the benefits that have been seen in the manufacturing industry to-date in regards to systems automation, advancements have been concentrated on the equipment/systems and LEAN initiatives. In a previous publication by Noventri, entitled “Manufacturing Technology: What Gets Measured Gets Done” we established the importance of manufacturing metrics being communicated to the workers. It has been common for those metrics to be displayed on Whiteboards or even LED Scoreboards; of which, are either manual or extremely limited in their use. Automating this communication process is key. Automatically pulling and displaying key metrics in real-time is extremely powerful. In a thesis titled “Metrics: You Are What You Measure!”2 by John R. Hauser and Gerald M. Katz, it states that those ‘…who know how to maximize [their metrics] fear to change course. It is extremely hard to refocus the enterprise on new goals.’ This can be seen in many organizations that utilize Manufacturing Metric Displays. As an example, workers can see that if they improve small aspects of their workflow, they can see substantial improvements to the manufacturing metrics on the Manufacturing Metric Displays. Once this happens, as was brought out by John R. Hauser and Gerald M. Katz, it’s incredibly difficult to move away from this mind set. Having the workers efforts in the form of metrics displayed in real time is gratifying and rewarding for the worker. Behind the scenes, those metrics sets just so happened to be hand selected by management as the key metrics they need to see improved for the plant. Aside from the power of automating these manufacturing metrics systems, manually publishing manufacturing metrics to workers is extremely time consuming and could result in hundreds, if not thousands of hours wasted. Implementing Manufacturing Metric Displays, and automating them with the manufacturing metrics collection systems, will not only provide the benefits of having a common cause, but will naturally LEAN up the workflows. What is the SIMPLE way to implement manufacturing metrics in this new era of automation?With the application of Manufacturing Metric Displays on the plant floor, employee common areas, and even metric displays in the executive offices, a new layer of automation can be implemented. The key is to utilize the capabilities of the Manufacturing Metric Display to pull manufacturing data from existing ERP or MES systems, working Excel sheets, recorded OEE data, SQL databases or anywhere else that the company performs their manufacturing data collection and analysis. Software such as Noventri Suite in conjunction with hardware such as the Noventri SF-200, can collect and gather data from any combination of those sources and then display this in an organized way on a ruggedized display in plain view of the workers providing all of the benefits mentioned above. A new era for automation in the manufacturing environment is here! For more information or to request a free demo click the button below. 1 Wikipedia.org, http://en.wikipedia.org/wiki/Automation 2 Picture adapted and quotes provided by MIT.edu, - http://www.mit.edu/~hauser/Papers/Hauser-Katz%20Measure%2004-98.pdf |

|

|

|

|

|

|