LEAN Six Sigma - Is There a New Methodology? |

When determining the methodology that is best suited for the LEAN Six Sigma project at your organization, one must consider; can there be a way to improve upon the methodology itself?

When determining the methodology that is best suited for the LEAN Six Sigma project at your organization, one must consider; can there be a way to improve upon the methodology itself?

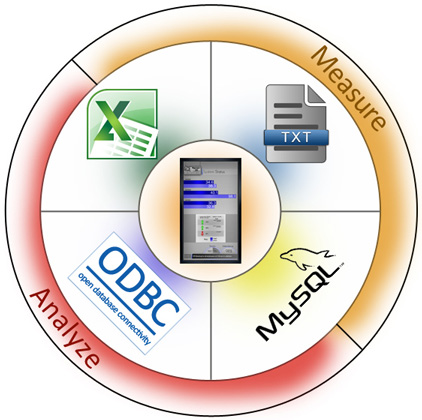

Why are methodologies used in a LEAN Six Sigma project? An article on isixsigma.com says "The fundamental objective of the Six Sigma methodology is the implementation of a measurement-based strategy that focuses on process improvement and variation reduction through the application of Six Sigma improvement projects." Since measurement strategy is one of the foundations in which LEAN Six Sigma rests, we must ask ourselves, is there more that can be done when going through the Measurement and Analyze processes? We are going to discuss one way in which you can shed more light on measuring and analyzing while going through the Define, Measure, Analyze, Improve and Control (DMAIC), and Define, Measure, Analyze, Design and Verify (DMADV), Six Sigma methodology processes. This can be done by displaying the progress of the project so as to have instant feedback for the project team. Displaying the progress can also contribute to the celebration process by displaying project completion results and it can also streamline the analyzation process. While the benefits are obvious, how would this work? After the Six Sigma project has been chosen and a Business Research Document (BRD) has been created, it is time to start the DMAIC or DMADV process. While doing this, it is crucial that the project metrics and Key Performance Indicators (KPI) are recorded in a way that analyzation can be achieved. Real-time monitoring of these KPIs can add a new dimension to the analyzation process in the DMAIC and even the DMADV methodologies. In essence, we can say that the methodology would be DMDAIC (Define, Measure, Display, Analyze, Improve, and Control) and DMDADV (Define, Measure, Display, Analyze, Design, and Verify). How do I display my LEAN Six Sigma metrics?While the KPIs and the other LEAN Six Sigma metrics are being recorded in a database (Excel spreadsheet, SQL database, text file or other ODBC databases), a Manufacturing Metric Display can automatically pull from the database or collection of databases, format the data into graphs, charts or tables, and then present the metrics that are needed during the DMAIC/DMADV process. This enables those in the Six Sigma project to capture real-time information so that they can take action.The key is to make this an automated process so that all efforts are focused on increasing productivity, while decreasing defects within the project. In order to accomplish this, a Manufacturing Metrics Display system would have to be selected that is capable of pulling this information automatically and to be EXTREMELY flexible in doing so. For more information on how Noventri Manufacturing Metric Displays will help with your Six Sigma projects, please click the "Request Info" button below. |

|

|

|

|

|

|